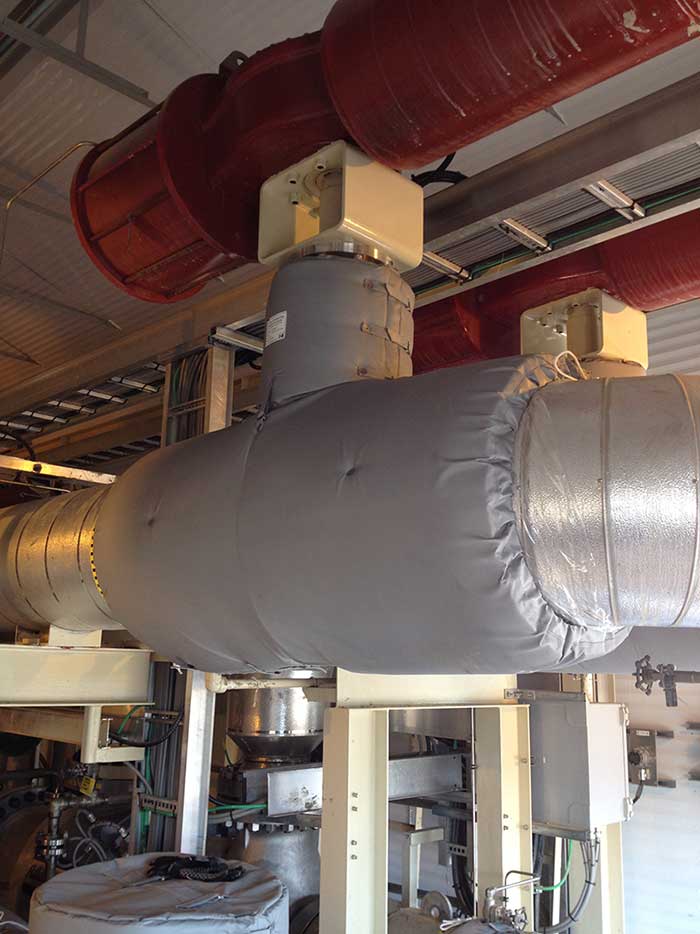

Insulation Covers

- Covers are user friendly, and any plant personnel can install or remove these covers in minutes.

- Being removable and reusable these covers are very cost effective in the fact that they can be reused after the equipment has been serviced or replaced.

- Removable covers will generally pay for themselves after the first maintenance cycle.

- Removable covers can be modified or repaired if any changes or damage may occur.

- The general features of the removable covers are; Durable, Flexible, Flame and Chemical Resistant.

- Each cover is custom designed to provide the proper fit to all equipment. The sealed ends and tailored fit will protect and reduce heat loss.

- When using an insulation cover system you can reduce waste by reusing the cover.

- During a plant turn around or maintenance check up the convenience of being able install the cover immediately will allow the processing equipment to be up and running very quickly.

- When the covers are being used on equipment with high operating temperatures the outside of the cover remains relatively cool, due to the quality and thickness of the insulation. This provides personal protection to any worker near the equipment.

- Each cover is complete with a visible identification tag on the outer jacket of the cover. This will allow the cover to be distributed to the right location, and be re-installed on the equipment the cover was built for.

Material supplied on removable covers operating from temperatures of - 40 to 500F

• 1750 Siliflex CL silicone cloth (inner/outer jacket)

• 1″ PPG mat insulation

• 2″ Velcro Laps

• E-18 Fiberglass sew thread

• SST D-rings, quilting pins and washers

• 1″ Re-enforcement straps

• HT Poly-cord pull-ties

• Sewn on ID label